Introduction

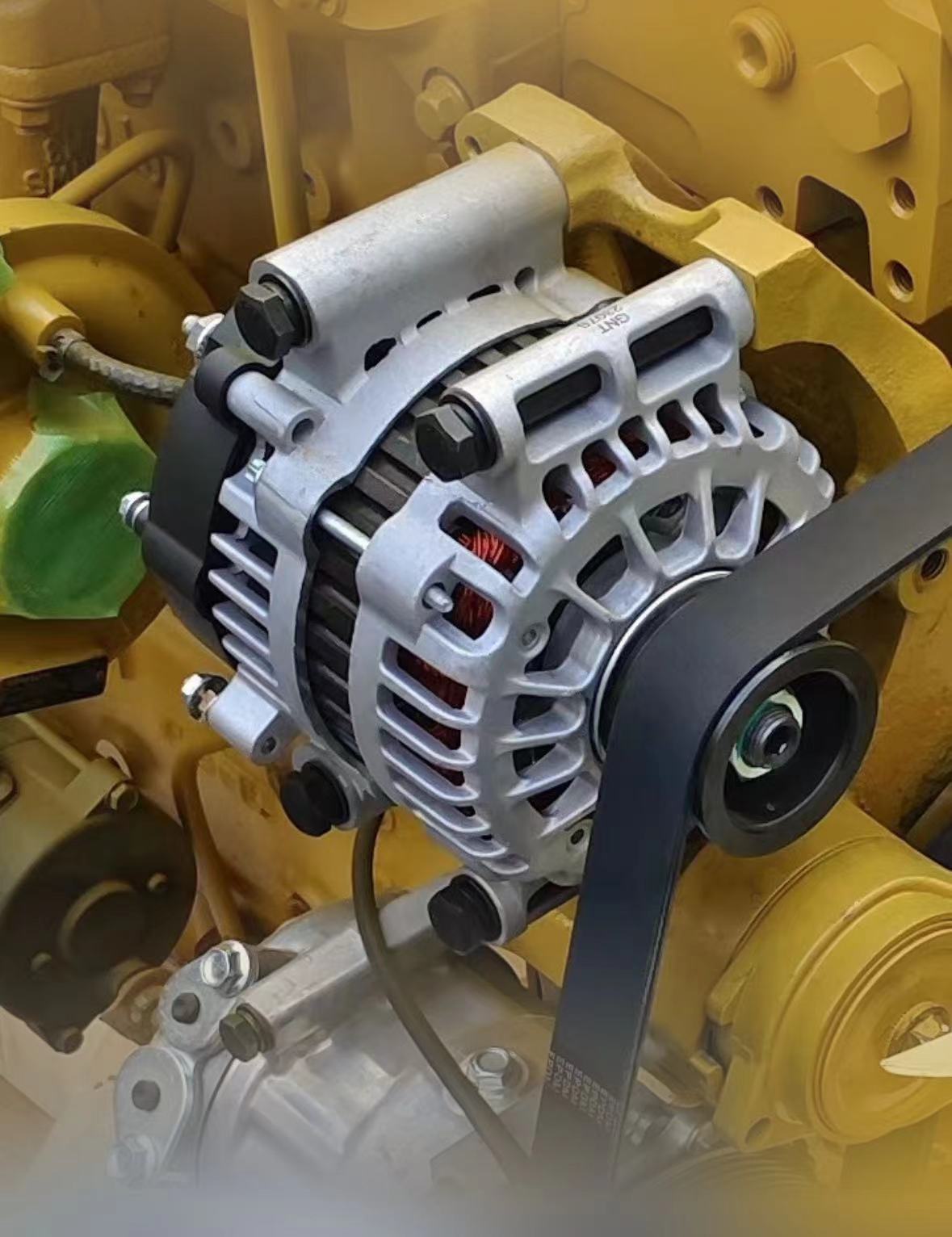

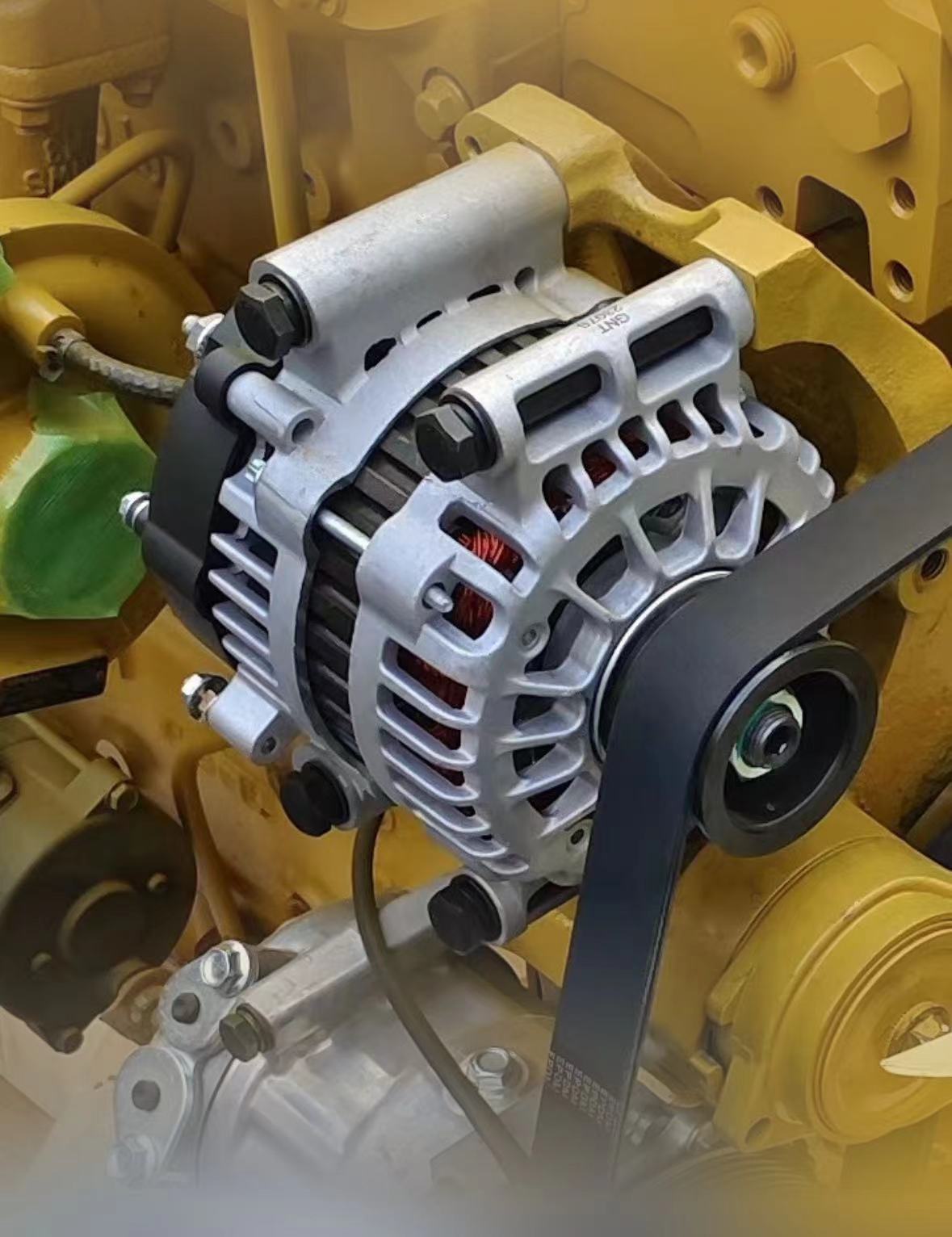

A conventional alternator consists of the following key components: rotor, stator, brush assembly, rectifier, cooling fan, pulley, and front/rear end covers.

Details

Rotor

The rotor generates the rotating magnetic field. Its key components include:

Two claw-pole segments (each with 6 bird-beak shaped poles) press-fitted onto the shaft

Field winding (exciter coil) wound around an iron core within the pole cavity

Two insulated slip rings that transmit DC excitation current to the winding via brushes

When energized, the field winding creates alternating magnetic polarity (N/S poles) between the claw poles, establishing six pairs of magnetic fields.

Stator

The stator assembly produces alternating current and consists of:

Laminated silicon steel core with insulated winding slots

Three-phase stator windings arranged in either:

• Wye (Y) configuration (most common): Phase leads connect to rectifier diodes, neutral ends joined at central point

• Delta (Δ) configuration

Brush Assembly

The brush system comprises:

Two carbon brushes (conduct excitation current)

Brush springs

Brush holder mounted on rear end cover

Rectifier

The diode rectifier converts three-phase AC to DC output:

Six high-current, high-reverse-voltage silicon diodes

Diodes mounted on heat sinks

Configuration:

• Positive diodes (anode terminal)

• Negative diodes (cathode terminal)

End Covers

Front/rear covers feature:

Aluminum alloy construction (non-magnetic, reduced flux leakage)

Lightweight design with superior heat dissipation

Brush holder integrated into rear cover

Ventilation ports for air cooling

Cooling System

The rotating assembly includes:

Drive pulley connected to engine via belt

Axial-flow fan mounted behind pulley

Airflow path:

• Intake through front cover vents

• Exhaust through rear cover vents

• Forced convection cooling during operation

0

0 Mar, 12, 2013

Mar, 12, 2013